January 21st, 2021

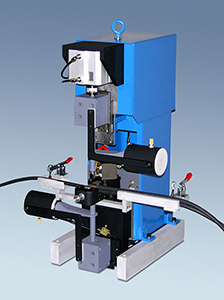

Sonobond Announces Advanced HMI for Improved Metal Welding Results

Customer Specifications Can Now Be Achieved With Greater Assurance By Using the Data-Driven Capabilities of Our Latest Innovation West Chester, Pa – January 21, 2021 – Sonobond Ultrasonics, the company […]